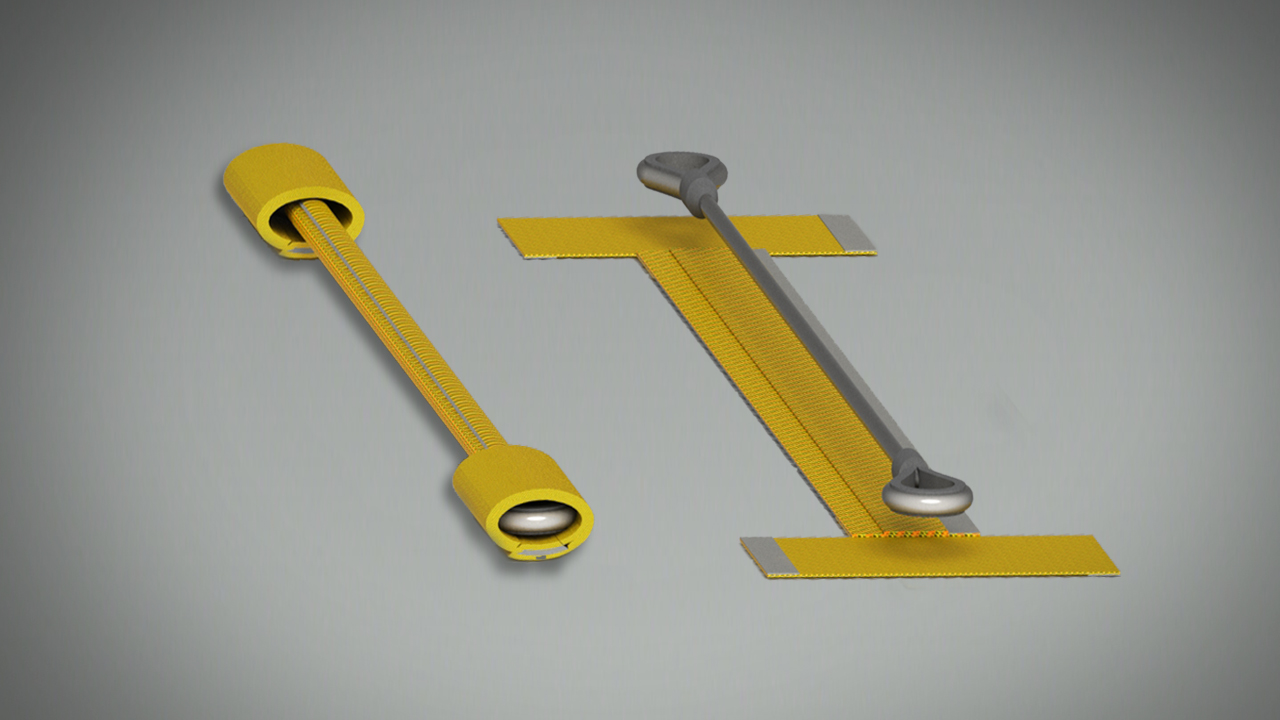

Wire Rope Protection Sleeve (WRPS)*

Is a user-friendly, high visibility protective cover created for use when handling high-spec tubulars and equipment. The WRPS eliminates contact between the load and lifting equipment.

The WRPS was designed with the intention of protecting 13%Cr, 25%Cr, etc. tubing from acquiring imperfections and thus points susceptible to accelerated pitting, corrosion, and other chemical and non-chemical reactions on surface and downhole caused by slings being slacked off from cranes and forklift forks during mobilization and handling.

The WRPS is easy to install and remove, thus permitting safe monitoring, inspection, and recertification of lifting equipment. It may be secured in standard or customizable lengths and diameters; and has the ability to protect thimble eyes and master links. The WRPS may be utilized on various basket designs, may be retrofit to existing in service equipment, or on standalone slings for bundling.

This provides

Protection of high-spec tubulars and equipment from localized damage during mobilization.

A means to eliminate the uncertainty of nylon strap condition for handling.

The ability to inspect and recertify wire rope slings and other handling equipment within currently existing protocols.

Features

High strength Velcro enclosure that will weather the storm of offshore conditions.

High visible structure to aid operators during day and night operations.

Customizable lengths and diameters.

Alternative ad-hoc uses include, but are not limited to:

Protection of hydraulic hoses from abrasive damage.

Identification of walkway hazards.

Cable bundling and protection.

*Patent Pending © 2015 Spoked Solutions. All rights reserved. V06.13.15